Making Tracks

With ever-growing pressures on mining operations, companies are reliant on the life span of their

equipment and mining fleet. Dozer equipment is often on the front-line of such operations. Dozer

operators should always check the dozer track’s tension is just right, to get the most out of their

equipment.

If a track is too tight, or too loose, its components will wear faster. On most dozers,

a coil

spring compresses or extends to take up small changes in track tension during operation. When the

tension of a track needs to be adjusted, a short stroke hydraulic cylinder filled with grease is

typically used.

The grease extends the coil spring which in turn drives the idler wheel to the desired position and

holds it there under retained grease pressure.

Root Cause of Failure

Having inspected metal structures and components for signs of fatigue stress for many years, Metal

Testing noticed a trend in the way dozer track adjusters were failing on welded joints.

KAM Mining investigated this trend further and managed to develop a track adjuster solution,

manufactured here in Australia, which could save companies up to four days of maintenance time and

extend the life of their track adjuster.

Slashing Maintenance Time by 80%

Typically, when a track adjuster breaks inside a dozer, it can take up to five days to strip the

dozer, remove the broken component and repair it. The KAM Mining track adjuster can be switched out

in a matter of hours to allow the equipment to remain operational.

The design allows for safe, simple access as the operator need only remove bolts to remove the

broken tensioner and vice versa to install a replacement.

This process could lead to an 80% reduction in track adjuster maintenance time. In addition to

maintenance time, companies may also need to wait for replacement parts from overseas, which has

proven

challenging through 2020 and could be equally challenging in 2021 and beyond.

The KAM Mining track adjuster provides companies with the option of sourcing equipment designed and

manufactured here in Australia, eliminating any associated international shipping cost.Safety in

Design

The conventional dozer track adjustment process comes with great risk if not undertaken properly and

particularly if the dozer and its components are not well maintained.

The uncontrolled release of energy poses a significant risk to maintenance personnel in the track

tensioning process.

The KAM Mining track adjuster Design

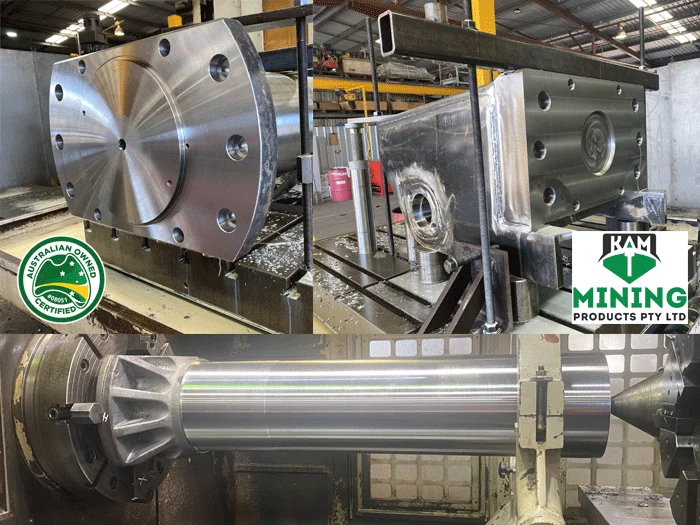

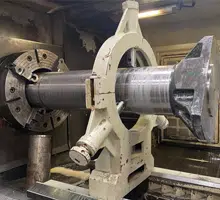

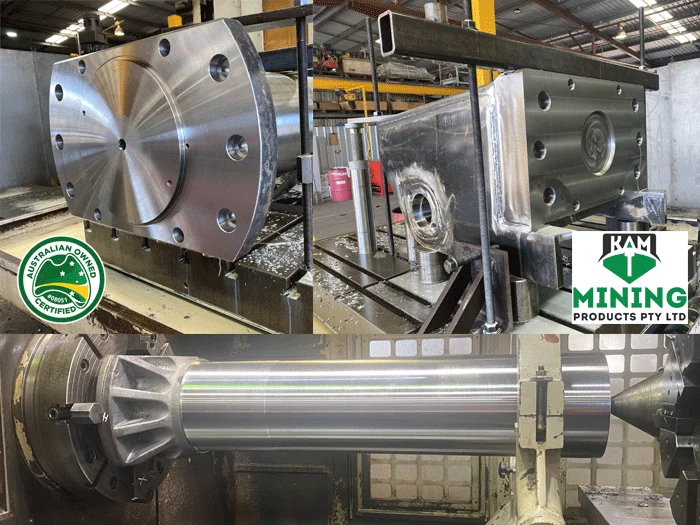

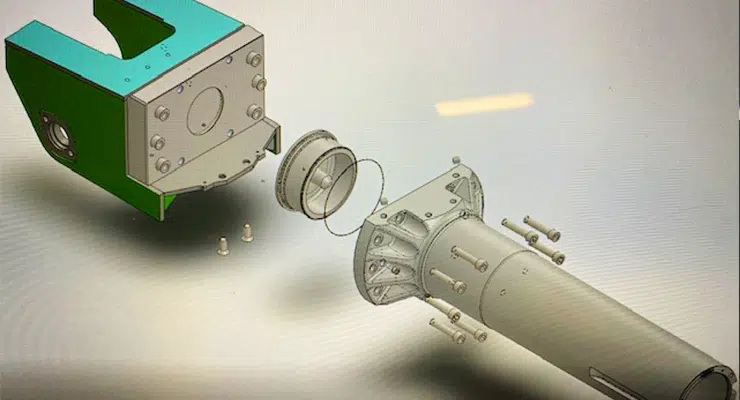

The KAM Mining track adjuster is designed, machined and fabricated in Toowomba, Queensland by

highly certified tradespeople.The company used finite element modelling techniques recognised by

Australian Standards to fine-tune their design. The shaft is made of one casting with excellent

tensile

strength properties and can be positioned in reverse if it wears on one end (in the keyway) doubling

its

operational life. The track adjuster comes with stress relief features.

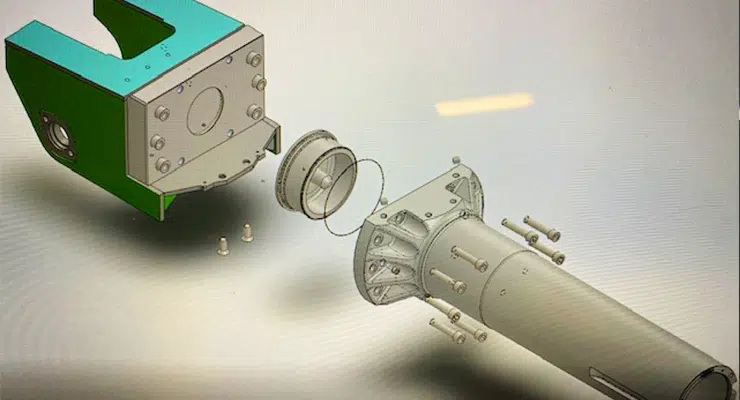

Dowels can be used to locate the shaft and support the assembly which reduces the stress typically

put

on the bolts. The track adjuster itself is split into two pieces and is held together as an assembly

with 10 bolts, making it easy to service. In the first design of its kind, the risk of the

uncontrolled

release of energy from the spring assembly has been eliminated. The spring assembly is sealed inside

the

track tensioning shaft which provides a physical barrier between personnel and the energy source.

KAM Mining will provide clients with certificates for every KAM Mining track adjuster

manufactured, which will state how the piece was welded and manufactured. It will also provide a

process

and chemical analysis and non-destructive testing record. Product Assembly and Disassembly Each Metal

Testing track adjuster comes with product assembly and disassembly instructions. The unit is simple to

assemble and disassemble but the work must be undertaken by a qualified tradesperson.

In a Nutshell

KAM Mining is a leading Australian non-destructive testing company which has taken a successful leap

from specialising in testing metal structures for fatigue stress cracking to engineering innovative

solutions to improve the design of the structures it inspects. “Our track adjuster is manufactured in

Australia. “Every part of the process, from scratch, is built to Australian Standards. “FEA analysis

has

proven positive results with the material grade we have chosen to cast the product in Queensland

Australia. We will be providing ongoing support with any parts purchased, and we are happy to

refurbish

parts to allow clients to swap them out easily.

“We are proud to say it’s made in Australia.” KAM Mining aim to be the leading supplier and

manufacturer of track adjusters in Australia.