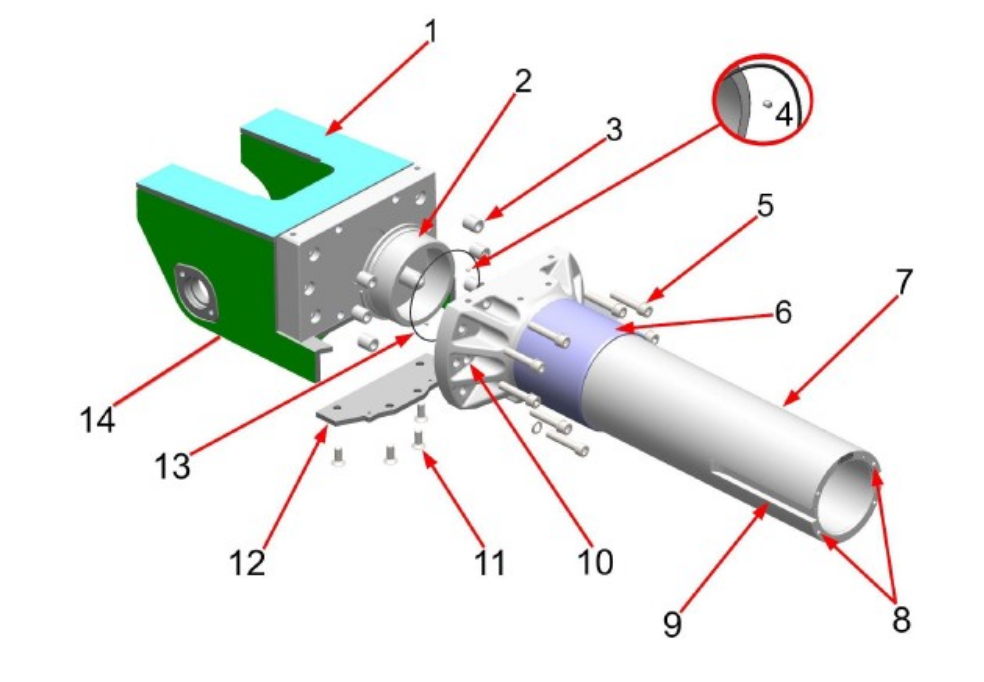

| S.No | Parts of the Tracks | S.No | Parts of the Tracks |

|---|---|---|---|

| 1 | Idler end | 2 | Inner boss |

| 3 | Dowels | 4 | Grub screws |

| 5 | Main bolts with Nordlock washers | 6 | Chrome sleeve |

| 7 | Cannot shaft assembly | 8 | Holes for the bolts to retain the stops |

| 9 | Keyways | 10 | Threaded holes to help remove the cannon |

| 11 | Bolts for the bottom plate | 12 | Bottom plate |

| 13 | O-ring | 14 | Holes to install the vibration pad (under the idler end) |

With ever-growing pressures on mining operations, companies are reliant on the life span of their

equipment and mining fleet. Dozer equipment is often on the front-line of such operations. Dozer

operators should always check the dozer track’s tension is just right, to get the most out of their

equipment.

If a track is too tight, or too loose, its components will wear faster.

On most dozers, a coil

spring compresses or extends to take up small changes in track tension during operation. When the

tension of a track needs to be adjusted, a short stroke hydraulic cylinder filled with grease is

typically used.

The grease extends the coil spring which in turn drives the idler wheel to the desired position and

holds it there under retained grease pressure.

If a track is too tight, or too loose, its components will wear faster. On most dozers, a coil

spring compresses or extends to take up small changes in track tension during operation.